How to Properly Store and Organize Rivets for Future Use?

When it comes to storing and organizing rivets for future use, it is important to take a few steps to ensure that your rivets remain in good condition. Here are some tips for properly storing and organizing your rivets:

1. Store your rivets in a dry environment with low humidity levels, as high moisture levels can cause corrosion and rust.

2. Sort your rivets into smaller containers or bags based on size and type for easier accessibility later on.

3. Label each container or bag with the proper specifications, such as diameter, length, material finish, and other details that will help you to find which ones are best for a specific job.

4. Keep your rivets organized and easy to access by using a wall-mounted organizer which can be purchased at most hardware stores.

5. Store the rivets away from any sources of heat, as excessive exposure to high temperatures can cause them to deteriorate faster over time.

By following these simple tips, you can keep your rivets organized and in optimal condition for future use. Maintaining an organized inventory of rivets ensures that you always have the right size and type of rivet material to get the job done.

Importance of Properly Storing and Organizing Rivets

A pop rivet, as well as other types of fasteners, are important components in many construction projects. It is essential to store and organize them properly so that they remain in good condition for future use. Unorganized rivets can easily become mixed up which could lead to a variety of problems down the line. Improperly stored rivets can also become corroded due to moisture and other environmental elements, making them unusable.

Taking the time to properly store and organize rivets ensures that they remain in optimal condition for future use. This will save you time and money in the long run, as it allows you to quickly locate the exact type of rivet diameter, solid rivet body, and rivet gun needed for a job. Keeping rivets properly stored and organized also guarantees that they will be in the best condition possible when it comes time to use them.

Choosing the Right Storage Containers for Rivets

When it comes to choosing the right storage containers for your pop rivets or any type of rivets, there are a few factors to consider. The container size should be large enough to hold all of your rivets and small enough to fit in the available space.

Sturdy plastic or metal containers with lids are typically best, as they protect your rivets from moisture and dust. It is also important to ensure that the containers are stackable, so that they can be easily stored in tight spaces. Transparent storage containers are also beneficial, as they allow you to quickly identify the different types of rivets without having to open each one.

Tips for Sorting and Categorizing Rivets by Size and Type

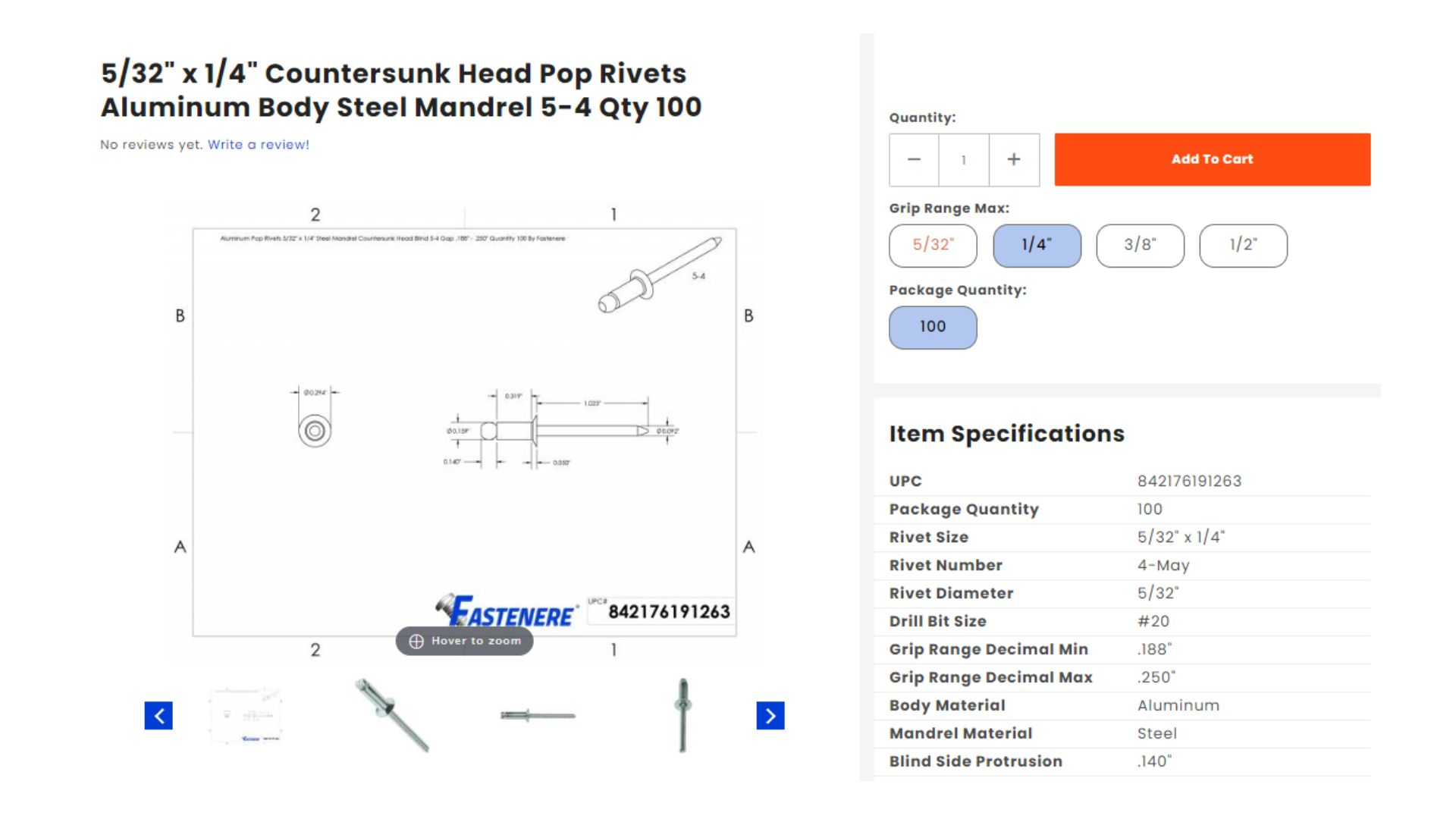

When it comes to sorting and categorizing rivets, one of the most important things to do is to separate them by size and type. Common types of rivets include flat-head, truss-head, countersunk, and dome head rivets. Once you have your rivets sorted into categories, use a label maker or a permanent marker to label each container with the specifications. This will help you easily identify which rivets are best for a specific job in the future.

Properly storing and organizing heavy duty rivets is essential for construction projects as it ensures that they remain in good condition and are easy to access later on. By following these tips, you can keep your rivets applications properly stored and organized so that you always have the right size and type available when needed.

Best Practices for Labeling Rivet Storage Containers

Labelling your rivet storage containers is an important step in keeping them organised. Labelling provides a quick and easy way to identify each type of rivet when needed, as well as ensuring that they are properly stored away from sources of heat. Here are some tips for labelling rivet storage containers:

1. Label each container with a permanent marker or label maker, clearly indicating the type of rivet and size.

2. Make sure to include the material used for each rivet (aluminum mandrel, stainless steel rivets, etc.).

3. Include any necessary information such as head diameter and length.

4. Keep a list nearby that outlines all containers and their contents, for easy reference.

5. Label containers with a “Do Not Use” sign if they contain rivets that are past their expiration date.

This will save you time and money in the long run, as it allows you to quickly locate the exact type of rivet needed for a job. Taking the time to properly store and label your rivets ensures that they remain in optimal condition for future use.

Creating a Dedicated Rivet Storage Area or System

Creating a dedicated rivet storage area or system is also an important step in keeping your rivets organized. Such an area should be kept away from sources of heat and moisture, such as windows or doors, to prevent damage. Shelves can be used to store containers and keep them off the floor. By creating a dedicated storage area or system, you can ensure that your rivets - such as steel rivets, blind rivets, and more - remain in good condition and are available when needed.

Overall, properly storing and organizing your pop rivets or steel rivets is essential for any construction project. Taking the time to create a dedicated storage area or system, sorting and categorizing rivet sizes and types, as well as labeling containers with clear specifications can save you time and money in the long run. Properly-stored rivets will ensure that your construction projects are completed safely and efficiently.

Maintaining an Inventory of Rivets for Easy Access

It is also important to maintain an inventory of aluminum pop rivets so that you know how many are in stock and when they need to be replaced. This can help prevent shortages as well as helping you keep track of the amount of money spent on supplies. An inventory system can also provide valuable information, such as which types of rivets are used most often or which ones are in high demand. Maintaining an inventory of your rivets will give you the knowledge to make informed decisions about the kinds and amounts of rivets that should be stocked for future projects.

Preventing Rivet Contamination and Damage During Storage

In addition to proper labeling and storage, it is important to also prevent rivet contamination and damage during storage. Contaminants such as dust, dirt, and oil can affect the performance of the rivets and lead to costly errors. Taking the following steps can help reduce contamination:

1. Use airtight containers or bags for storage.

2. Wipe down countersunk head pop rivets with a damp cloth to remove any dirt or debris before placing in storage containers.

3. For stainless steel rivets, use a lubricant such as WD-40 to prevent or resist corrosion and rusting while in storage.

4. Store the containers away from direct sunlight or moisture sources.

5. Make sure the containers are kept away from any heat source, as this can cause rivets to become soft and malleable.

By taking these steps, you can ensure that your rivets (or any other rivet types such as countersunk head pop rivets, blind rivets, solid rivets, copper rivets, brass rivets, countersunk rivets, friction lock rivets, semi tubular rivets, structural steel rivets, flush rivets, metal rivets, stainless rivets, low carbon steel rivets, countersink rivets, bifurcated rivets, aircraft rivets, split rivets, self piercing rivets, drive rivets and more) remain in top condition for future use or construction projects. Proper storage is essential for ensuring the longevity and proper functioning of your rivets.

Proper Handling and Packaging of Rivets for Long-Term Storage

When handling and packaging rivets like large flange aluminum rivets for long-term storage, there are several steps to take.

- Firstly, it is important that all containers are clearly labeled with the type of rivet, size, and expiration date so that you know which boxes contain expired or outdated rivets. It is also important to sort through your containers regularly and discard any expired rivets.

- Secondly, it is essential to use the correct packaging materials for your large flange aluminum alloys rivets. Sturdy plastic bags or containers should be used to protect them from moisture and contamination.

- Lastly, it is important that all containers are stored in a cool, dry place away from sources of heat and moisture.

By following these steps, you can ensure that your rivets for long-term storage remain in good condition and are available when needed. Proper handling and packaging of your rivets will also help to extend their working life and reduce the risk of costly errors or delays caused by damaged or contaminated supplies.

Regular Maintenance and Inspection of Rivet Storage System

Regular inspection and maintenance of your pop rivets, blind rivets, and other rivets storage system is essential for ensuring the safety and efficiency of any construction project. With the right methods in place, you can ensure the safety and efficiency of your projects while reducing costs and delays due to damaged supplies or contaminated materials. By following these steps, you can guarantee the highest quality of work for any project.

FAQs

How should I store my rivets to prevent damage?

Store rivets in a dry, low-humidity environment away from heat sources. Use airtight containers to prevent moisture, and ensure proper labeling for quick access.

What is the best way to sort and categorize rivets?

Sort rivets by size, type, and material. Label each container with clear specifications like diameter, length, and finish for easy identification.

What type of containers are ideal for storing rivets?

Use sturdy, stackable plastic or metal containers with lids. Transparent containers help you quickly identify rivet types.

How can I prevent rivet contamination and corrosion?

Keep rivets clean and dry. Use a damp cloth to remove debris before storing, and apply a lubricant to stainless steel rivets to prevent rust.

Should I maintain an inventory of rivets?

Yes, maintain an inventory to track stock levels, identify popular sizes, and prevent shortages, ensuring you always have the right rivets available.

How can I create an efficient rivet storage system?

Designate a dedicated area with shelves for organizing containers. Keep this area away from heat and moisture to prolong rivet lifespan.

How often should I inspect my rivet storage?

Regularly inspect storage for contamination or damage, and sort out expired or corroded rivets to maintain an efficient and safe inventory.